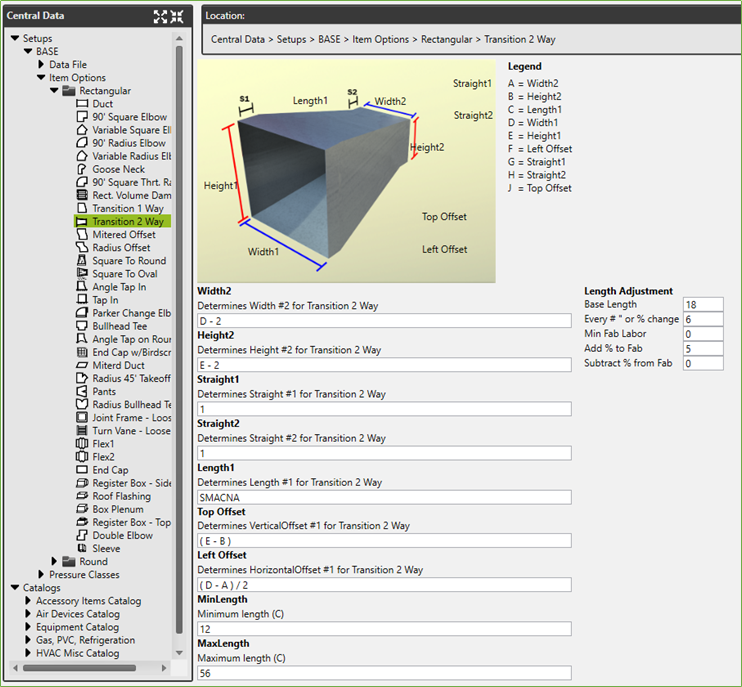

Click a Rectangular Duct item in the navigation tree to see the options available for that item. Using the 2way Transition as an example, this section will explain some of the options available. Understanding the options for one item will help you better set up the others.

Width 2 and Height 2 – set the default reducing amount

Straight 1 and Straight 2 – inches of straight after the transition

Length 1 – enter SMACNA to use the 15 degree rule or a formula

Top and Left Offsets – default amount to offset the duct item

Minimum and Maximum Lengths – set the limits for short and long transitions

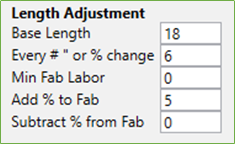

Length Adjustment

The pressure file handles the standard fabrication of an item based on an average or base length. If that length is adjusted by the user in takeoff, apply an adjustment.

Base Length – average length for a transition through the center line length of the item.

Every # of Inches or % of change – enter a number to state the length adjustment threshold or a number with the percentage symbol to have the adjustment based of a percentage of growth

Min Fab Labor – since the labor can be reduced, set a minimum fab labor for the item if desired.

Add % to Fab – the percentage the item fabrication labor (pressure file labor) should be increased.

Subtract % from Fab – the percentage the item fabrication labor (pressure file labor) should be decreased.The Item Options section of the Central Data allows for customization of the fabrication and takeoff of the items.

| Child pages (Children Display) |

|---|