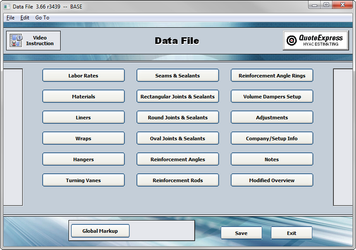

05. Data File

The Data File is an accumulation of data (a library) that is required for the processing and building of your duct and pipe systems. This information is all collectively stored here for ease of use by QuoteSoft Duct in the construction standards and Takeoff module.

This is the area where you will keep all of your data for such things as your labor rates, liner, wrap, hanger systems, etc. All of this information should be updated and checked regularly or as often as possible.

This information will be used in the specific pressure files that you create for your company and that of your customer’s files as well.

This data is important to the program and it is strongly recommended that you password protect these files to keep unnecessary changes from being made.

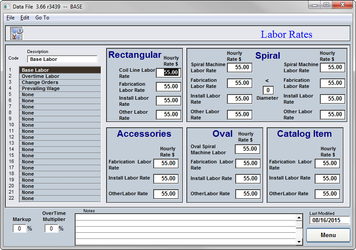

Labor Rates

Labor rate information library; QuoteSoft Duct uses the dollar amounts input here, multiplied by the number of hours calculated during takeoff to get the labor cost for each item. You can store up to 22 different labor rate cost data with separate rates for Rectangular, Oval as well as Spiral / fabrication, installation and engineering and drawing (Other).

Rectangular labor rates are divided into three different sections; Miscellaneous labor rate, Fabrication labor rate and Install labor rate.

Miscellaneous labor (Other) is for your hours used in shop drawings, submittals, O&M’s, etc. These are your hours that are not direct install or fabrication hours.

Fabrication labor is the labor rate for manufacturing your ducting systems.

Install labor is the labor rate for installation of the ducting systems and their accessories.

With the Spiral Rates, you do the feature of charging a higher labor rate if the spiral’s diameter is greater than that of 26 inches. If this is not the case please input the same rate in both fields.

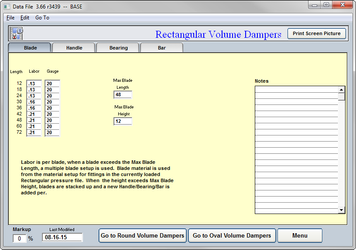

Volume Dampers

QuoteSoft Duct advanced volume damper set-up.

This advanced set-up in the Data File is only necessary if you wish to have more control over your blade, bearing and handle labor and material for your volume dampers. Typically if you are building your multi-blade dampers you need to use this Advanced Volume Damper Setup.

Most QuoteSoft Duct users use standard volume damper set-ups in the Accessory File. The standard Accessory File volume damper set up is used with price/labor by size category or quoted volume dampers.

To have accurate labor and construction standards for building your volume dampers, you need to modify the national standard generic volume dampers data, with your data of how you build volume dampers. For this to be done correctly you will have to setup the proper standards for the blades, handles, bearings and for the bar. This data will aid QuoteSoft Duct in constructing your volume dampers.

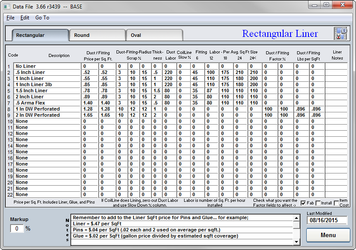

Liner

Liner information library; Enter your standard liner information. Data can be any “interior treatment” to the duct, pipe and fittings such as Liner, paint, lead, powder coat, etc. The liner library has separate inputs for rectangular, round and oval liners. The listed liners can be applied during takeoff. Liner can be specified and automatically input per pressure file. Liners can also be limited per pressure file.

- Description

This is the term or name of your liner that you use. - Price Per Square Foot

The per square foot cost of the liner plus the cost of the glue and the pins. - Duct/Fitting Scrap Percentage

The percentage of liner scrap for straight duct as well as fittings. - Fitting Labor

The number of square feet of liner that can be installed on fittings per hour. The average square foot sizes are listed. - Liner Notes

Notes for each liner such as special purchasing instructions, special pricing, etc. - Notes

This is for special instructions or important data about the liner.

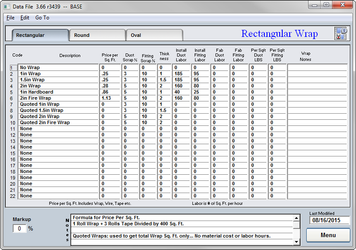

Wrap

Wrap information library; enter your standard duct wrap information. Wrap can be any exterior treatment to the duct, pipe and fittings such as paint, lead, powder coat, etc. The wrap library has separate inputs for rectangular, round and oval. The listed wraps can be applied during takeoff. Wrap can be specified and automatically input per pressure file. Wrap can also be limited per pressure file. Wrap can be setup for sq ft. collection only, and used for an quoted subcontract.

- Description

The name or term you use for the wrap. - Price Per Square Foot

The total cost of the wrap per square foot including the tape, tie wire, etc. - Duct Scrap

The amount of scrap created in wrapping straight duct. - Fitting Scrap

The amount of scrap created in wrapping fittings. - Thickness

The thickness of the wrap. - Duct Labor

The number of square feet of wrap per hour that is used in wrapping straight duct. - Fitting Labor

The number of square feet of wrap per hour that is used in wrapping fittings. - Wrap Notes

Specific notes on each individual wrap such as special wrapping instruction or where it was purchased. - Notes Field

Any note pertaining to wrap or this central data file.

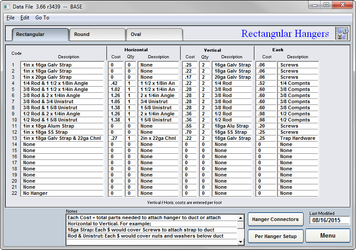

Hangers

Hanger information library; enter your standard hanger information. The hanger library has separate inputs for rectangular, round and oval. The default hangers can be changed anytime during takeoff. Default hanger sare specified and automatically input per pressure file. Hanger availability can also be limited per pressure file.

- Code

This is the code you will assign in your pressure files as to default hanger system to use. - Description

Description you wish to use for your hanger systems. - Vertical Cost

The cost of the material per foot that is vertical in the hanging system. - Vertical Description

The description of the vertical material. - Horizontal Cost

The cost of the material per foot that is horizontal in the hanging system. - Horizontal Description

The description of the horizontal material. - Each Cost

This is the cost of the miscellaneous items required in installing the hanger system. - Each Description

Just the term you wish to use to describe the miscellaneous items.

The information on your hangers and their respective systems should be kept up to date. This data will help FABshop calculate the most correct pricing for you.

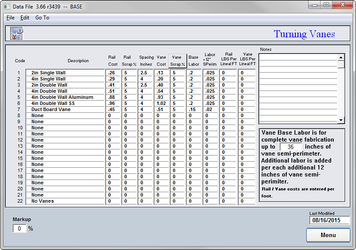

Vane

The information about the type of turning vanes you use, buy or sell is to be stored in this section of the Data File. The data will be used later when you are creating your own customized pressure files, either general ones or company specific pressure files.

- Code

This is the code you will assign in your pressure file to accurately select the proper turning vane. - Description

This is the terms or the names of the vanes that you use for your reference. - Rail Cost

The per foot cost of the rails required for these specific turn vanes. - Spacing Inches

The number of inches required in between the vanes. - Vane Cost

The per foot cost of the turn vane. - Shop Labor

The amount of labor required to fabricate vanes up to the size of 24″ x 12″. - Labor + 12″ Perimeter

Additional labor is added for every 12″ of perimeter. This will ensure that the proper amount of labor is calculated for the proper size of turning vanes.

The turning vane information is used in the construction of your elbows and tees. This data is added to the base calculation of costs and labor for fabrication of these fittings.

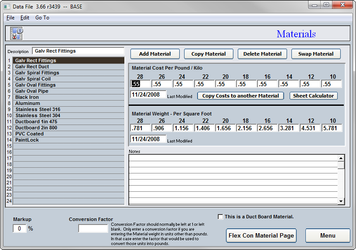

Materials

To add a new material click on the “Add New Material Type” button and enter the name of the new material to create. Then you will have to update the material costs per pound and the material weight per square foot.

When creating a new material type you may wish to copy one already created and make modifications to it. To do this click on the button “Copy Material Type” and give the new material a unique name. Then adjust and customize the material data as needed.

To delete a material type click on the “Delete Material Type” button and you will be asked if you are sure you wish to delete the currently viewed material type, then click ok or cancel to either delete the material type or cancel the process.

You can also rename a material type by clicking on the button “Rename Material Type”. This will allow you to take an already existing material and give it a new name.

The material cost per pound for each of your different material types should be kept as current as possible, this to ensure the proper calculations will be made on your material costs.

The material weight per square foot will also need to be input to make sure that the proper amount of pounds will be calculated for your bid or job.

Scrap percentage is set in independently in each pressure file. To set scrap – open the pressure file, click the scrap button and set scrap for each type and size of item.

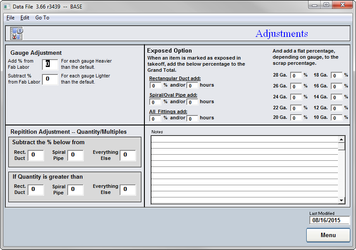

Adjustments

- Gauge Adjustment

You can add a percentage from your fab labor for each gauge that is heavier than your default gauge. This is here because of the difficulty involved in working with the heavier material. You can also subtract a percentage from the fab Labor for lighter gauges, as they are generally easier to work with and quicker. - Repetition Adjustment

Here you can subtract a percentage from your fab Labor. This is used for multiples of the same fitting. The reason behind this is that the more you make of the same thing the quicker it will go. - Exposed Option

When you have exposed ductwork or Pipe you will want to spend a little more time on it, beautifying it basically. No one wants to look at banged up duct. These fields are here to add to the grand total of the job. The gauge selection to the right directly relates to the exposed option. For instance if you drop an elbow and it is to be exposed, you more than likely throw it away, creating more scrap.Add a flat percentage, depending on gauge to the scrap percentage. Each gauge of metal has varied scrap. When a default gauge is overridden this adds an additional percentage to each gauge’s scrap factor. - Notes

Enter specific notes and instructions pertaining to this page.

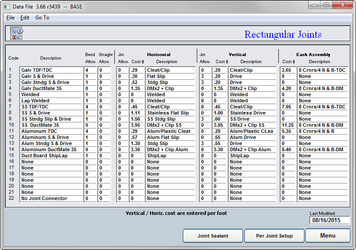

Rectangular Joints

The central library of rectangular joints; cost and labor data per each and per size range are specified here. The individual “rect pressure files” (construction standards) use this library of joints to specify the exact joint per size range to other fittings.

- Code

This is the code in which you will assign in the pressure files. That will establish which joint system is to be used on your ducting. - Description

The terminology or brand name you use to describe your jointing systems. - Allow

This is the bend allowances that are needed in creating the joint system. - Vertical Cost $

The first is the actual dollar amount of the joint system in a per foot format. The second entry would be the description of the costs. - Horiz. Cost $

The same as the vertical costs. - Each Cost $

The first entry is the dollar amount for the each items. The second is the miscellaneous items required in assembling the joint system. - Per Joint Labor

The per joint labor is the actual labor required to fabricate and install specific joint systems onto the ductwork. On this page all of the joint systems will be listed for you to click on and enter in the proper amount of hours for fabrication as well as installation.

If you check the box that asks if you wish to include connection fab labor on duct, QuoteSoft Duct will add these hours to the straight duct as well.

Assembled Labor (This area is only used if you are not installing the ductwork, only selling it assembled)

The assembled pricing page lists the hours required to assemble the ductwork in the specific seam categories. The hours must be entered if you wish to have the hours for assembling the duct included into the price of your bid or job.

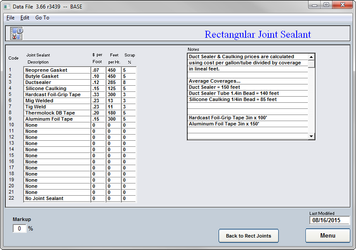

Rectangular Joint Sealants

The sealants that are used for your rectangular joints on the transverse joints (S and Drive, TDC, etc.) are listed on this page. Information as the price per foot and the number of feet per hour need to be provided.

- Joint Sealant Description

Description of the sealant being used to seal the rectangular joints. - $ Per Foot

The cost per foot for the joint sealant. - Feet Per Hr.

The amount of feet per hour that can be sealed using the specific joint sealant. - Scrap %

Percent of joint sealant that is wasted or unused.

This information is required so that the program will correctly calculate the hours for labor and the costs for your joint sealant systems.

Round Joints

The central library of round joints; cost and labor data per each and per diameter are specified here. The individual “round pressure files” (construction standards) use this library of joints to specify the exact attachments per diameter to other fittings.

- Code

This is the code you will be selecting in your pressure file to select a joint system. - Description

Whatever terms or description you use to describe your round joint systems. - Allow.

These are the allowances that need to be listed for each system so the program can calculate the proper amount of metal. - Per Foot Cost

This is the per foot cost for each of the round joint systems. - Each Cost

Miscellaneous items required in the joint systems independent of round joint diameter.

Per Diameter Cost

The round per diameter cost and labor information is listed here. If you are using spiral couplers than the cost of the complete coupler should be listed. If you were using spiral mate rings then the complete cost for the two rings should be input. The joint system is determines the cost that must be listed.

- Allowed Sealants Per Joint

The sealants that you wish to have allowed for each joint system should be checked. These sealants will be listed in the alternate menus in Takeoff. These sealants will only be listed if they have a check next to them. - Scrap %

This percentage will be added to your per diameter cost as a waste factor for each joint system. - Cleats Per Ft.

Is used if there are cleats involved in the joint system. The amount of cleats used on a per foot basis. If you put one cleat every 6 inches then you should use the number 2 in the amount of cleats per foot, and so on. - Screws Per Ft.

If the particular joint system has screws involved in the connection or fastening then you should list the number required per foot. If you use one screw on either side of the spiral coupler every 6 inches then the number of screws per foot would be 4, and so on.

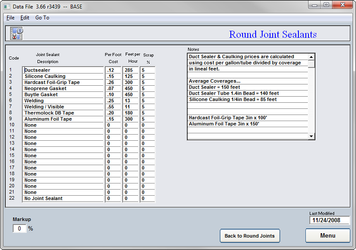

Round Joint Sealants

The sealants for your round joint systems are listed here.

- Joint Sealant Description

Name or the term used to describe the joint sealant system used with a specific joint connection. - Per Foot Cost

The per foot cost of the joint sealant. - Feet Per Hour

Amount of feet per hour that can be sealed. - Scrap %

Percent of joint sealant that is wasted or unused.

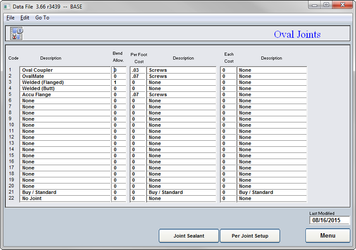

Oval Joints

The central library of oval joints; cost and labor data per each and per size range are specified here. The individual “oval pressure files” (construction standards) use this library of joints to specify the exact joint per size range to other fittings.

- Code

This is the code you will be selecting in your pressure file to select a joint system. - Description

Terms or description you use to describe your round joint systems. - Allow.

These are the allowances that need to be listed for each system so the program can calculate the proper amount of metal. - Per Foot Cost

The per foot cost for each of the oval joint systems. - Each Cost

Miscellaneous items required in the joint systems that are calculated per joint regardless of size.

Per Diameter Cost

List the actual labor required to fabricate and install the joint system onto the flat oval pipe or fitting. Each joint system can have the hours input by selecting the type of joint system and inputting the hours by the correct diameter of pipe.

- Flat Span Price Per Foot

The cost of just the flat side of the joint system. - Flat Span Minimum Price

This is the minimum price that is to be used in calculating the flat span costs.

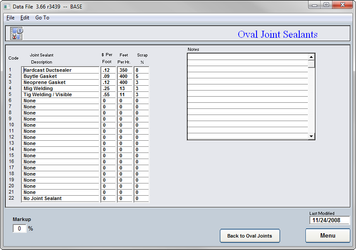

Sealant

The sealers that are used with your oval joint systems are listed on this page. QuoteSoft Duct will use this data to determine the cost of sealing your oval pipe and fittings.

- Joint Sealant Description

The name or the terms you use to describe the joint sealant used with this specific joint connection. - Per Foot Cost

The per foot cost of the joint sealant. - Feet Per Hour

This is the amount of feet per hour that can be sealed.

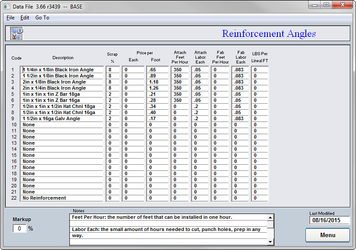

Reinforcement Angles

The angles that will be used as for stiffening the ductwork are input here.

- Code

The code that will be assigned in the pressure files. - Description

The name or terms used to describe the angles that are to be listed. - Price Per Foot

The cost by the foot for the angle. - Feet Per Hour

The number of feet per hour that can be installed. - Labor Each

The amount of labor required to install each set of angles. - Notes

A notes field for your use.

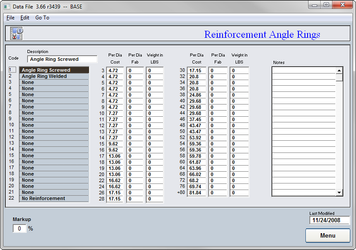

Angle Rings

The angle rings that are used as intermediate stiffeners for spiral and oval pipe need to be listed here. This data will be applied in the pressure files.

- Code

Code that will be selected in the pressure files. - Description

Name or term used to describe the angle ring that is to be listed. - Per Diameter

Cost of the angle ring for each specific diameter - Notes

General notes field for your use.

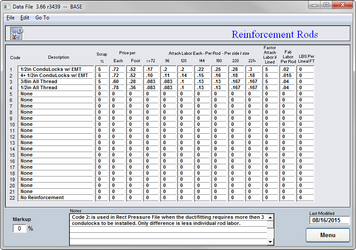

Reinforcement Rods

The rod information that is to be input on this page is the data on the stiffening rods that are used in your shop.

- Code

Code that you will assign once you are in the process of building pressure files. - Description

Terms or brand names that are used in describing the rods that are to be used. - Price Per Each

The miscellaneous components required to install the rods. - Price Per Foot

The per foot price of the rod itself. - Labor Each - Per Rod - By H + W of Duct

The amount of labor to install the rods and their components up to and rounded to a specific size. - Notes

General notes field for your use.

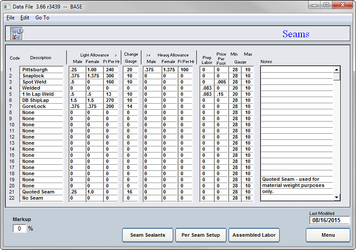

Seams

Central library for all seams; Including the seam material allowance for male and female sides of the seam, the cost per foot, labor data, and feet per hour and labor for each are specified here. The individual “pressure files” (construction standards) use this library of seams to specify the exact seam per duct and pipe size based off big side of the rectangular duct, or diameter of round, or major axis of oval pipe and fittings.

- Code

The code that will be chosen to reflect the seam in the pressure files. - Description

Terms or names that will represent the seams available. - Light Allowance

- Male

The number of inches used in turning the male of the seam.

- Female

The number of inches used in turning the female of the seam.

- Male

- Feet Per Hour

Number of feet per hour of the seam that can be done. - Change Gauge

Gauge at which the turning of the seams requires more metal. - Heavy Allowance

- Male

The number of inches used in turning the male of the seam.

- Female

The number of inches used in turning the female of the seam.

- Male

- Feet Per Hour

Number of feet per hour of the seam that can be done. - Prep. Labor

Labor required in preparing the ducting for the seam. Aligning the seams to be mig welded, for example. - Price Per Foot

The price per foot for consumables (wire, gas, etc.) - Gauge

- Minimum

The smallest gauge that is allowed to have this seam.

- Maximum

The largest gauge that is allowed to have this seam.

- Minimum

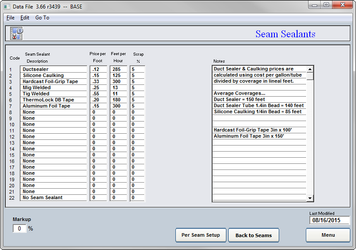

Seam Sealants

This is your central library of seam sealants; cost per foot and labor data feet per hour are specified here. The individual “pressure files” (construction standards) use this library of seam sealants to specify the exact sealants per seam per construction standard. All data for rectangular round and oval seam sealants are entered here.

- Code

The line number used in the pressure file to select a certain seam sealant. - Seam Sealant Description

Names of the available seams sealants. - Price Per Foot

The price per foot of seam sealant. - Feet Per Hour

The amount of feet of seam sealant that can be applied per hour. - Notes

Use this space to enter notes. Include information about why you set up this screen. When was it created and/or modified. Details on any changes made to the screen, etc.

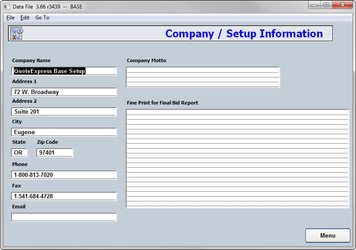

Company Information

Enter your corporate data onto this page.

QuoteSoft Duct uses these entries on reports and Excel exports in the pertinent locations.

Listed should be all of the information such as:

- Company Name

- Address

- City

- State

- Zip Code

- Phone

- Fax

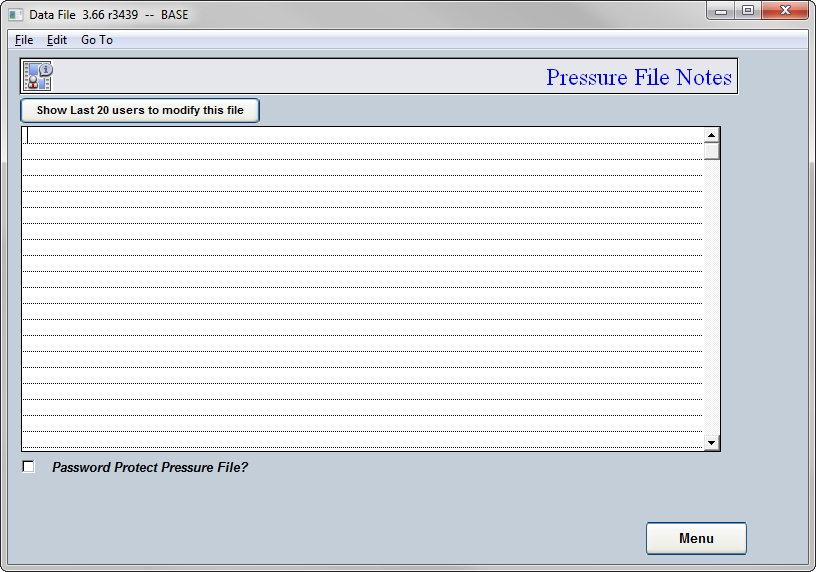

Notes

This is a general notes field for your use.

Password protecting the data file can be done from here.

Simply check the box asking to be password protected.

View password will allow you to view the pressure file but not make any changes.

The Edit password will allow you free reign of the pressure file.

Show the last 20 users to modify this file. Shows user, time, date, and computer used in last 20 modifications to this data file.

If there is a need to print out a text copy of the data file click on the “Print All Data” button from the main menu of the data file. Select “Yes” to confirm printing. WARNING this will print the screens and data from all pages in your pressure file. 40+ pages.

To print an individual page click on the “Print Screen Picture” button located on each input screen.

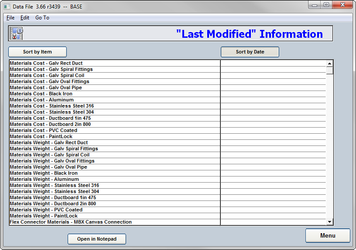

Last Modified Information

Use this page to see when the last time the material and labor rate data was modified.

To print an individual page of data click on the “Print Screen Picture” button.

To export data only click on the “Open Data in Notepad” button QuoteSoft Duct will export the data to Windows Notepad program and allow you to browse the data and select the data to print or use in email or other programs.

©2022 ConstructConnect, Inc. All rights reserved.