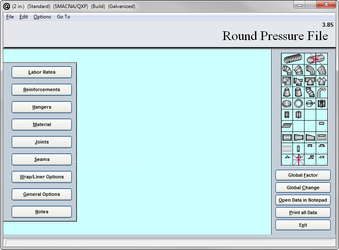

08. Round Pressure File

This is the location of all of the data and labor for your round pipe and fittings. You can have multiple pressure files for different kinds of ductwork systems including aluminum, stainless steel, low pressure, medium pressure and many more.

While in the takeoff module, the program will read the pressure file to determine what values to access for labor and costs. The round pressure file is where all of your data will be stored and read by the program for your round pipe and fittings.

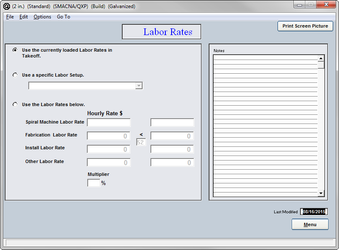

Labor Rates

The labor rates that you enter in here will be used unless you check the box at the top of the page telling FABshop to use the rates you have set up in the Data File. The reason you have the ability to set up the rates twice is for those pressure files you have to set up that are different than what you would normally do and require a higher labor rate.

The three different labor rates you have to enter are for your Miscellaneous, Fabrication and Install rates. You also have the option to have the rate change at a specific diameter. This will allow you to charge more for the larger diameter piping.

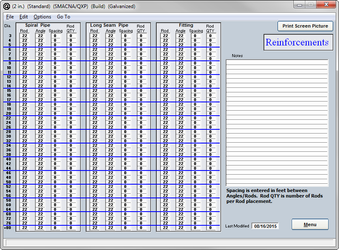

Angle Rings

The angle rings are the reinforcements that are to be used for round pipe. (If any) The data that you established in the Data File will be pulled and applied here. Enter the default (standard) code you want applied for this round construction standard (pressure file) This enables the specific angle ring for each diameter pipe or fitting to be automatically selected and calculated on your pipe and fittings, during takeoff.

- Dia.

This is the diameter of the pipe that is being worked with. - Spiral Pipe

- Angle

This is the code that was set up in the Central Data File.

- Spacing

The spacing in between the angle rings on the pipe in inches.

- Angle

- Fittings

- Angle

This is the code that was set up in the Central Data File.

- Spacing

The spacing in between the angle rings on the pipe in inches.

- Angle

- Angle Rings

This is the list of angle rings that you have set up in the Central Data File.

When you click into the angle rings that are listed to the right, the list will be removed and become a blank notes field for you to store your comments.

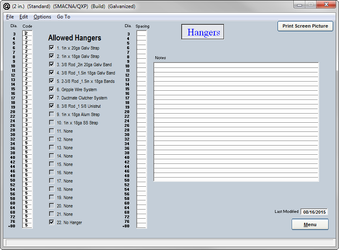

Hangers

Enter the default (standard) hanger code you want applied for this round construction standard (pressure file) This enables the specific round hanger for each diameter pipe or fitting to be automatically selected and calculated on your pipe and fittings, during takeoff.

- Dia.

The diameter of the pipe that you are working with. - Code

This is the code you gave to the hangers in the Central Data File. It must be specified as to which code is to be used for which diameter. - Hangers

This is a list of the codes and systems that were established in the Central Data File. - Notes

If you click into the notes field the hanger information will be removed and you can type your notes specific to this hanger’s page in its place.

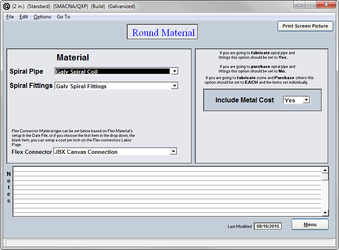

Materials

The material for your round pipe in this pressure file is selected from the drop down lists. The materials that are listed are the ones that were setup in the Data File. The proper material type should be selected for the pipe and for the fittings.

- Include metal cost

- Yes

This should be selected if you plan on fabricating all of your round pipe and fittings.

- No

This is if you are purchasing all of your pipe and fittings.

- Each

If you fabricate some and purchase some, then this option should be chosen.

- Yes

The materials page should be kept current with your selections; this will ensure that the program is calculating the correct values for you.

Joints

The round joint information that was input into the Data File will be used here. Enter the default (standard) joint code you want applied for this round construction standard ( pressure file) This enables the specific round joint for each size pipe or fitting to be automatically selected and calculated on your pipe and fittings, during takeoff.

- Dia.

The diameter of the pipe. - Joint

This is the code that was established in the Central Data File. - Gauge Pipe

For this diameter of pipe what gauge do you wish to use. - Gauge Fitting

For this diameter of fitting what gauge to you wish to use. - Spiral Length

For this diameter of pipe, the standard length of pipe. - Long Seam Length

The standard length of your long seam pipe. - S-Pipe Scrap

The scrap percentage when making spiral pipe. - LS-Scrap

The scrap percentage when making long seam pipe. - Fitting Scrap

The amount of scrap when fabricating fittings. - Joints

When you click into the joint column the list of joints that are in the Central Data File will appear in the notes field to the right. - Notes

If you click into the notes field to the right the joint data will be removed and you will have an area to type your notes.

If you wish to change any of the scrap percentage columns to one value, simply click on the column heading and enter in the percentage that you wish to use.

When you click into any of the columns you will see a series of check boxes to the right, which ever of these are checked will be listed in takeoff as an alternate

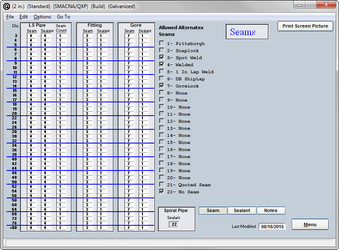

Seams

Enter the default seams for this round construction standard (pressure file) This enables the listed seams to be automatically be input on your pipe and fittings during in takeoff.

- Major Axis

The flat of the pipe, the longer dimension. - Spiral Sealant

The sealant that is to be used on the seam of the oval pipe. - LS-Pipe

- Seam

Which seam that is to be used for the long seam pipe.

- Sealant

The sealant that is to be used on the seam for long seam pipe.

- Seam

- Fitting

- Seam

Which seam that is to be used for the fittings.

- Sealant

The sealant that is to be used on the seam for fittings.

- Seam

- Gore

- Seam

Which seam that is to be used for the gores.

- Sealant

The sealant that is to be used on the seam of the gores.

- Seam

- Allowed Alternate Seams/Sealants

This section lists the seams and seam sealants that are available in the Central Data File. Each will have a checkbox that allows them as an alternate available in takeoff.

To get a notes field simply click into the area and the list of seams or sealants will be removed.

At the bottom of the page there is an entry to input the sealant that is to be used on the spiral pipe if any.

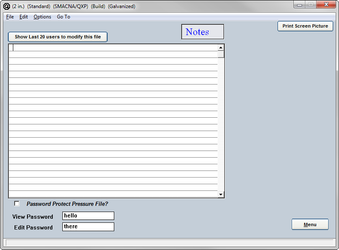

Notes

For notes on the pressure file such as when it was created, why it was created or modified, you should use the notes page. This will help to ensure that the pressure file is not changed or deleted without a record being listed as to why and by whom.

To password protect the pressure file simply check the box below and you will be given two passwords.

- View Password

This password will only allow you to login and view the file. No changes that are made will be saved or applied. - Edit Password

This password will allow you full access to the file.

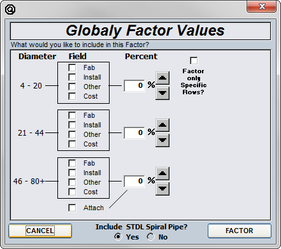

Global Factor

To globally factor the entire pressure file either up or down by a percentage, simply click on the “Factor” button from the pressure files main menu. Then select whether it is the fab, Install, Other or Cost values that you are wishing to change. It is not recommended to change all of the values at the same time because you will notice that each of the options will need to be lowered or raised a different percentage than the other.

After a choice has been made as to which values are going to be factored, you must then select a percentage. Simply use either the up or down arrows to change the percentages to the desired value.

The option of whether to include pipe should be unchecked for the most part. Generally when you are decreasing or increasing your values, you will notice that the pipe will either need to be raised or lowered by a larger percentage than that of the other fittings. Pipe should be factored separately and manually.

If there is a need to print out a text copy of the pressure file click on the “Print All Data” button from the main menu of the pressure file. Select “Yes” to confirm printing. WARNING this will print the screens and data from all pages in your pressure file. 40+ pages.

To print the data only click on the “Open Data in Notepad” button. QuoteSoft Duct will export the data to Windows Notepad program and allow you to browse the data and select the data to print.

To print an individual page click on the “Print Screen Picture” button located on each input screen.

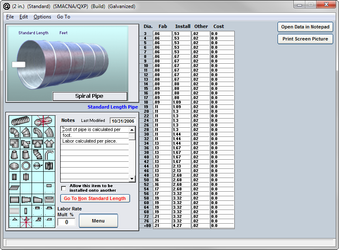

Spiral Labor

As soon as the changes have been made to the data part of the pressure file, it is time to make changes to the labor factors. Simply click on the icon of the fitting you wish to begin with.

The spiral pipe labor is broken into two separate categories; standard lengths and non-standard lengths.

The labor for spiral pipe, whether it be install or fabrication, is calculated using the per piece method. Either in standard lengths or in non-standard lengths. Anything shorter than that of a standard length will have the same labor factor no matter what the length.

Costs or prices for the pipe should be entered by the foot to ensure proper calculations. The weight of the pipe is also entered using the per foot basis.

On the materials page there was a selection that needed to be made, whether material costs were to be included. The options were Yes, No and Each. If each was selected then the check box on this page asking to include material costs should be checked. This will tell Server to include the cost of the material required to fabricate the item.

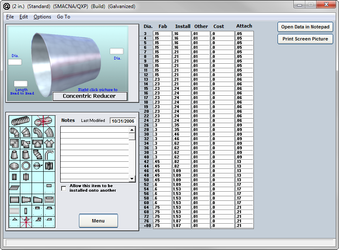

Fitting Labor

The labor hours for fabricating and installing your fittings and attachments should be input here in order to ensure that the program will be calculating the proper values for the fittings you are selecting in takeoff.

In Server the wyes for example are not calculated by the wye, they are calculated by adding the labor values and the weights for the body and taps that you select. The labor and weights for the collars and the reducers are added as well.

The fab column is the labor to fabricate the fitting that is selected.

The Install labor is the labor required to install that item, whether it be on pipe or on a wye.

The Weight column shows the weight of the fitting you have selected. If it is a tap, or body for example, these weights will be added together to give you the weight of the wye.

If these fittings in your Round Pressure File are going to be a bought item, the cost of the item should be put in the proper column. There is also a check box at the bottom of the page that is asking you to include the Metal costs that should be checked.

©2022 ConstructConnect, Inc. All rights reserved.