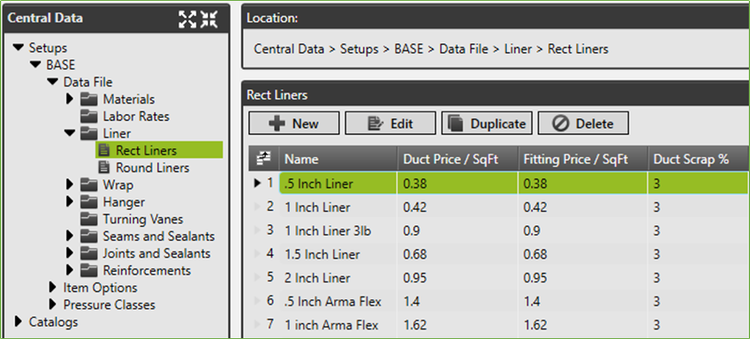

D. Data File - Liner

The Liner section of the Data File is separated by type, Rectangular and Round. Each type can have the same liner name, but the cost and labor factors can be different so they are setup separately.

Setup Data can be any “interior treatment” to the duct, pipe and fittings such as liner, perforated or solid metal, etc. The listed liners can be applied during takeoff. Liner can be specified as a default to be automatically used per pressure file. Liners can also be limited per pressure file.

The name and the thickness of the Liner are critical to be the same as you will select the liner by the name in Takeoff and the program will upsize the outer dimensions based off the thickness. There are no limits to the number of Liners you can have setup.

For Liner Calculations visit this page

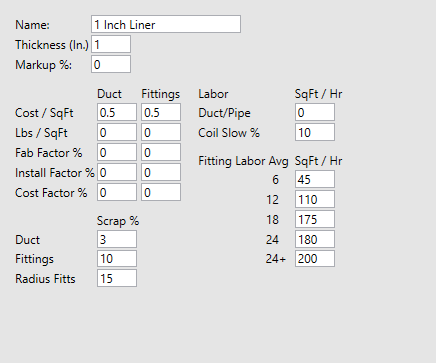

Liner Setup

Click New, Edit or Duplicate to add or modify the liner information.

Name - This is the term or name of your liner that you use

Price Per Square Foot - The per square foot cost of the liner plus the cost of the glue and the pins

Duct/Fitting Scrap Percentage - The percentage of liner scrap for straight duct as well as fittings

Fitting Labor - The number of square feet of liner that can be installed on fittings per hour. The average square foot sizes are listed

Duct/Fitting Fab Factor Percentage – to increase fab labor when a liner is applied (for double wall) enter the factor you wish used

Duct/Fitting Cost Factor Percentage – to increase material cost when a liner is applied (for double wall) enter the factor you wish used

Duct/Fitting Pounds per Square Foot – to include additional weight when a liner is applied (for double wall) enter the weight you wish used

Coil Slow % - If the coil line applies the Liner then the duct liner labor should be adjusted. Some coil lines have two settings, duct without liner is produced faster than duct with liner. The Duct SqFt/Hr will be set to 0 and the slow down rate will be input as a percentage.

Example: If applying liner to the coil line duct slows the production rate by 10%, input a 10 as the slow % (as shown above)

©2022 ConstructConnect, Inc. All rights reserved.