I. Data File - Joints and Sealants

Rectangular and Round joints are priced and labored differently so they are setup on separate pages. The sealants are combined into one page to keep from having duplication. There is no limit to the number of joints or sealants you can have in the program.

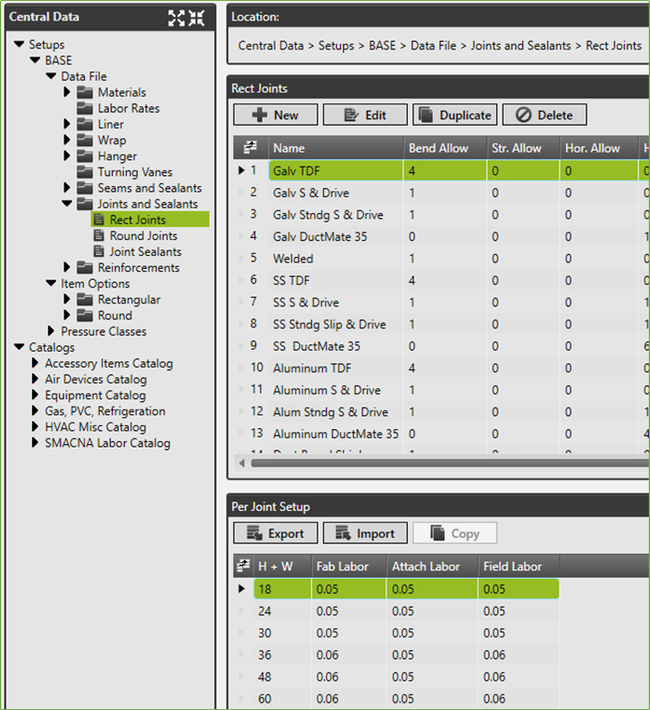

Rectangular Joints

Click New, Edit or Duplicate to modify joint information.

The Joints page has two lists. The top list has the name of the joint and the associated allowances. As well as costs required. The lower list has the labor required for the joint fabrication, attachment, and field installation.

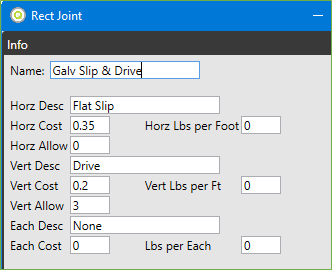

1. Rectangular Joint Setup

Select a joint in the top list and click Edit to view Per Joint Setup information

Name – the name of the joint assembly

Horz Desc – the name of the horizontal portion of the joint assembly

Horz Cost – the per foot cost of the horizontal portion of the joint assembly

Horz Allow – any additional inches that should be added to the calculated length of the horizontal portion of the joint assembly

Horz Lbs per Foot – the weight per foot of the horizontal portion of the joint assembly

Vert Desc – the name of the vertical portion of the joint assembly

Vert Cost – the per foot cost of the vertical portion of the joint assembly

Vert Allow – any additional inches that should be added to the calculated length of the vertical portion of the joint assembly

Vert Lbs per Foot – the weight per foot of the vertical portion of the joint assembly

Each Desc – the name of the miscellaneous portion of the joint assembly (nuts and bolts, etc)

Each Cost – the total cost of all the miscellaneous components

Lbs Per Each – the weight of all the miscellaneous components

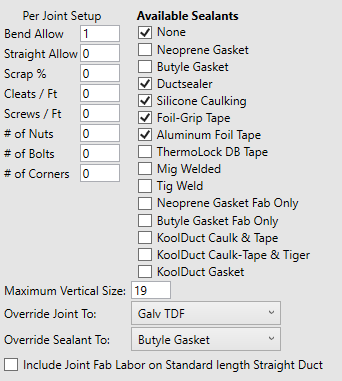

2. Per Joint Setup - Rectangular

Bend Allow – the inches to subtract for the joint connection

Straight Allow – additional inches of straight to add to transitioning duct items before the joint is applied

Scrap % - the percentage of scrap to be applied to horizontal and vertical calculations

Cleats per Foot – the number of cleats per foot

Screws per Foot – the number of screws per foot

Quantity Nuts – the count of nuts for each joint connection

Quantity Bolts – the count of bolts for each joint connection

Quantity Corners – the count of corners for each joint connection

Max Vertical Size – the maximum height this joint can be used with

Override Joint To – if the max vertical is reached, what joint to change to

Override Sealant To – if the max vertical is reached, what sealant to change to

Include Joint Fab Labor - If coil line options have been enabled in the Item Options setup for Duct to not include the joint labor (example; TDF or Slip and Drive formed during coil line process), but this joint requires the labor to be included as the coil does not provide the joint, then check this option.

Available Sealants – the sealant list is pulled from the Joint Sealants page. Check the sealants that are allowed with the joint.

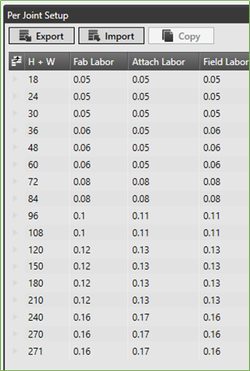

Per Joint Labor

Select a joint in the top list, you can then use Export button in the lower list to export the labor to excel and make changes. Then use the import button to update the joint with the changes made.

H + W – the height plus the width (semi-perimeter) of the duct item

Fab Labor – labor for each duct item of a specific size

Attach Labor – labor to attach the joint or components to the duct item (ductmate frame, corners for TDC, etc). The attach labor is added to fab labor in takeoff.

Field Labor – labor for field installation or connection of the joint assembly.

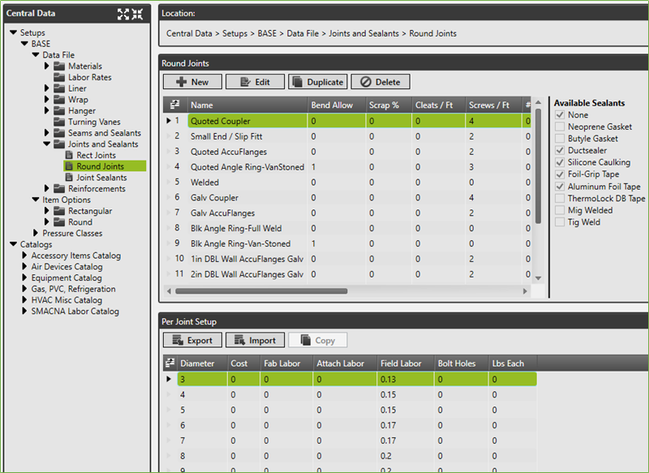

3. Round Joint Setup

Click New, Edit or Duplicate to modify joint information.

The Joints page has two lists. The top list has the name of the joint and the associated allowances. As well as costs required. The lower list has the labor required for the joint fabrication, attachment, and field installation.

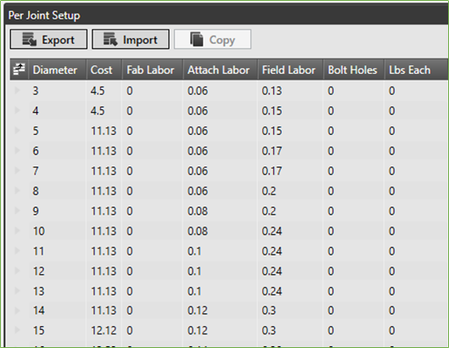

Per Joint Labor

Select a joint in the top list, you can then use Export button in the lower list to export the labor to excel and make changes. Then use the import button to update the joint with the changes made.

All changes are immediate on items taken off after the import.

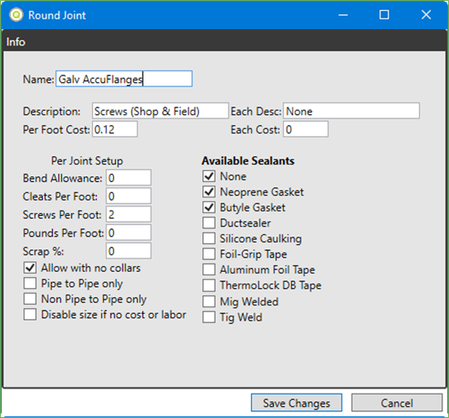

4. Per Joint Setup - Round

Select a joint in the top list and click Edit to view Per Joint Setup information

Name – the name of the joint assembly.

Description – the name of the circumference portion of the joint (screws, bolts, etc)

Per Foot Cost – the cost of the circumference portion

Each Desc – the name of the each components

Each Cost – the cost of the each components

Bend Allow – the inches to subtract for the joint connection

Cleats per Foot – the quantity of cleats per foot of circumference

Screws per foot - the quantity of screws per foot of circumference

Pounds per foot – the weight to include per foot of circumference

Scrap % - additional scrap to include for circumference calculations

Allow with no collars – if collars are removed from a round tee or cross is this joint allowed

Pipe to Pipe only – will only be applied in a pipe to pipe connection situation (couplers)

Non Pipe to Pipe only – will only be applied on fittings

Disable size if no cost or labor – if a cost and labor value is 0 the joint will not be allowed

Available Sealants – the sealant list is pulled from the Joint Sealants page. Check the sealants that are allowed with the joint.

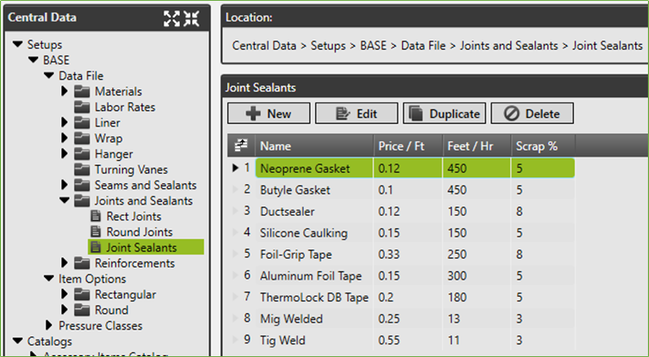

5. Joint Sealants

Name – the name of the seam sealant

Price/Ft – the cost per foot of seam for the sealant

Feet/Hr – the labor required to seal one foot of seam

Scrap % - the percentage of scrap to apply per foot of seam

©2022 ConstructConnect, Inc. All rights reserved.